Master Machinery Technology

(formerly Master Machinery Corporation, MMC)

Very high throughput up to 40,000 UPH, ideal for mass production

Test Handlers, Sorting Machines, Pick & Place Machines

Standalone or Custom Designed Vision Inspection, Lasermarker, Tape & Reel

In-Tape AOI System, Test-Mark-Tape

Pick and Place

Test, Mark, Tape, and Reel

Automated Optical Inspection

Loading Equipment

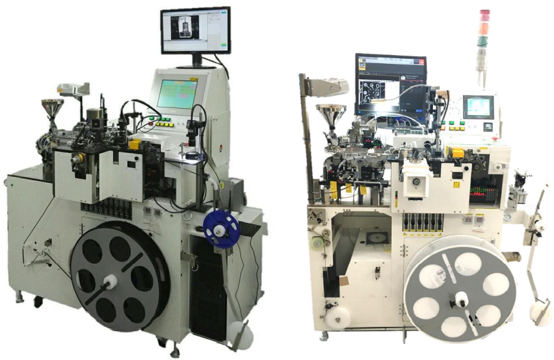

High-Speed Test Sorter

Trim and Form

Marking Equipment

SMD TMT Handler

All-in-One Assembly Solution (Customized)

Pick and Place

Input: Wafer, Waffle pack, Bowl Feeder, Tape & Reel

Output: Waffle pack, Tape & Reel

Speed: Up to 20k UPH

Size: 12-300mils

Packages: Bare Dice, SMD, CSP

Automatic Potting Machine

Features:

Potting Assembly

Quick Swap Syringe Assembly

4-Syringe Dispenser Assembly

MUSASHI Controllers

Auto Tray Input and Output

Automated Optical Inspection

Best in-line solution for optical inspection (2D/3D)

Type: LED Light source

Customized software interface

Variation of filters to detect different parts of die during inspection

Loading Equipment

Packages: SMD, Chip and Bare Die,

Axial, Power Packages, Diodes

Lead: Copper

High Speed Test Sorter

Input: Vibrating Bowl Feeder, Linear track

Output: Tape & Reel

Speed: Up to 270k UPH

Packages: Resistor, Capacitor, Inductors, Oscillators, ICs, QFN, SOT, SOP, TO, SMD

SMD TMT Handler

Packages: Micro SMP, SOT

Test: Polarity and Vision Inspection 6-side AOI

Speed: Up to 20k UPH

Tape & Reel System

Configuration: 24-head Turret head, Bowl feeder, Tester

Assembly Equipment

Application: Smoke Detector Parts

Solution:

Bowl Feeder Inputs

AOI System

20-Position Turret

Lead Cutting Assembly

LED Forming and Insertion

Laser Marker and Tape & Reel